|

|

| 為您提供液化石油氣,瓦斯車等產品 |

萬能工業 >瓦斯車 |

|

DISTRIBUTORSHIP |

We do represent the following excellent product. brand. Providing you with a prefect combinantion of LPG system. Just contact us ! for more!

Valve - Japan

|

RMG Meter - Germany

|

Seismometer Akashi - Japan

|

Teikoku Pumps - Japan

|

LPG Station Invoice printer

Auto Gas pos-4000 Class I, DIV I, Group D UL Certificate

|

Our Performance

- 1. Planning, design, construction and investment of Car-LPG filling

station.

- 2. Planning, design, construction and investment of LPG cylinder filling

plant.

- 3. Landtransportation of LPG and various chemicals.

- 4. Manufacturing of various pressurized vessel (1 ton - 500 tons) and tanker.

- 5. Manufacturing of forced vaporizer of LPG (50kg - 2000kg/hr).

- 6. Importation of industrial valves, regulator, mixer, pump, compressor,

seismometer.

- 7. Manufacturing of combustible gas detector.

- 8. Annealing equipment.

- 9. Processing labor inspection and annual inspection of pressure association.

- 10. Processing for the application of assessment held by china petroleum.

- 11. Processing for the inspection of normal pressure liquid tanker body.

LPG SYSTEM

Vaporizer

Vaporizer-Water Bath. Elec. Control

| Model |

Vaporization capacity kg/hr |

Heater/PCS |

Voltage |

Current |

Water Volune |

Weight (kg) |

Hydrostatic pressure kg/cm2 |

Hermetic pressure kg/cm2 |

| STSV-50 |

50 |

7.5kw |

220/380/440 |

24 |

140 |

200 |

27 |

18 |

| STSV-100 |

100 |

15kw |

220/380/440 |

60 |

160 |

400 |

27 |

18 |

| STSV-200 |

200 |

2×15kw |

220/380/440 |

120 |

220 |

450 |

27 |

18 |

| STSV-300 |

300 |

2×22kw |

220/380/440 |

160 |

250 |

550 |

27 |

18 |

| STSV-500 |

500 |

2×30kw |

220/380/440 |

256 |

450 |

950 |

27 |

18 |

| STSV-600 |

600 |

2×45kw |

220/380/440 |

320 |

500 |

1050 |

27 |

18 |

| STSV-1000 |

1000 |

4×38kw |

220/380/440 |

600 |

1000 |

1200 |

27 |

18 |

| STSV-2000 |

2000 |

5×60kw |

220/380/440 |

1200 |

1800 |

1600 |

27 |

18 |

Tank Lorries

Semi-trailer 19 Ton |

Cylinder filling site 30Tx4 |

Spheric tank 500Tx4 |

Tank lorry 15 Ton |

Chemical lorry |

|

LPG

lorries & semi-trailers

| Model |

Chassis |

Tare weight (kg) |

Laden weight (kg) |

Volume m3 |

| Semi-trailer |

ZO |

12500 |

19500 |

4465 |

| Tank lorry |

8.1 |

5800 |

3110 |

9.40 |

| Tank lorry |

15 |

10310 |

6190 |

16.0 |

| Semi-trailer |

12×2 |

8500 |

14850 |

23.50 |

Tanks

| Meet the CNS 2654 and JIS-B8242 specification the design pressure of LPG tank up to 18kg/cm2, the stock mass production steel plate of our company is SPV450 (steel plate used in transportation vehicle exceed 15 tons and fixed tank exceed 30 tons). The welding method of the tank is submersible arc automatic welding, and weld run are detected X-ray (100%). Tank body annealed heat treatment(625±25℃), water pressure test to 27kg/cm2. The tank body perform 2 grade sand blast treatment after completion of processing and apply two layers of organic zinc powder premier paint and 2 epoxy resin acid resistance finishing. |

Specification of LPG

| Standard spec.(Ton) |

φD(m) shell |

L(m) Length |

(m3)

Safety capacity (note 1) |

(m3)

capacity note |

| 1 |

1220 |

1570 |

3.50 |

2.35 |

| 4 |

1800 |

3050 |

9.40 |

9.4 |

| 5 |

2000 |

3050 |

11.50 |

11.8 |

| 10 |

2200 |

5700 |

23.00 |

23.5 |

| 19 |

2200 |

10640 |

42.00 |

44.65 |

| 20 |

2500 |

9000 |

45.50 |

47 |

| 27 |

2500 |

12000 |

56.70 |

63 |

| 40 |

3500 |

8400 |

84.60 |

94 |

| 50 |

3500 |

11100 |

105.70 |

116.3 |

| 60 |

3500 |

13500 |

128.00 |

142.05 |

GAS

DETECTOR

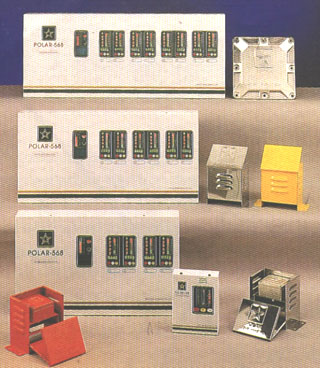

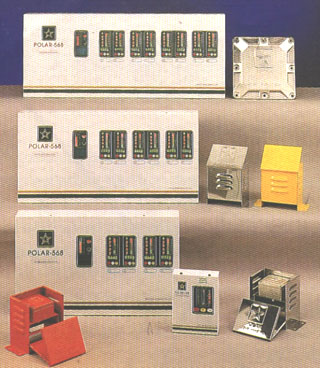

POLAR-568 GAS

DETECTOR

POLAR-568 Gas Detector

- Accepts from one to ten remote sensors

- Auto-Install feature simplifies set up

- Super bright barred LED array provides quick indication of normal, fault

and alarm conditions

- Simple calibration for all sensors

- Loud audible alarm

- Combustible gas sensors are mounted in an explosion proof housing

- Housed in a weather stainless steel enclosure

- Easy to follow instructions on an internal LED for calibration, alarm setting,

and concentration values.

Wall Mounted Controller

One to Ten Channel Gas Monitoring System

Gas Type: Combustible

- Range: 0-100% LEL, 0~18000ppm

- Inputs: One to ten remote sensors

- Input Power:Ac110/220V*50/60hzr

- Current Consumption: 0.2A protected by a 0.5A fuse

- OperatingTemperature:-10℃ to 60℃

- Operating Humidity: 0-95% Non-Condensing

- Case Material: Steel

- Dimensions: (mm)

| Type |

W |

H |

T |

| 568-2 |

350 |

350 |

80 |

| 568-4 |

580 |

350 |

80 |

| 568-6 |

710 |

350 |

80 |

| 568-8 |

850 |

350 |

80 |

| 568-10 |

980 |

350 |

80 |

Area Classifications: General Purpose

- Sensors: Class I, Division I, Groups C/D areas

- Combustible: Explosion-proof, suitable for Class I, Division I, Group C/D

hazardous location

- Display: Barred LED

- Buttons: 3 buttons for: Reset, Test, and Stop

- Internal Relays: Common low, high and fault alarms, form C contacts rated

at 5 Amps/250VAC

- Alarms: latching or non latching emergence or de-emergence relay

- Audible alarm: 100 dB @ 1 ft (30cm)

- Calibration Time Out: User adjustable from OFF to 100 minutes

- Calibration Reminder: User adjustable from OFF to 180 days

- Approvals: UL classified

- Warranty: One year materials & workmanship

- Safe T Net 100 DC power supply with battery backup. Wall-mounting.

Provides more than 8 hours of battery operation in the event of a power

failure. 110/220VAC input, 12VDC output, 14AH

- Red beacon 115VAC, weatherproof, non-hazardous areas optional

- Alarm horn, 115VAC, weatherproof, non-hazardous areas optional

Area POLAR-568 Gas Detector

1. Sensor & Transmitter

Specification

| 1.1 |

Type: diffusion catalytic type. |

| 1.2 |

Explosion: proof housing. |

| 1.3 |

Electrical classification: Class I, Div. I, Group C/D, certified by

UL |

| 1.4 |

Drift: less than 5% per year. |

| 1.5 |

Life: up to three years at normal service. |

| 1.6 |

Ambient temp.: -10 ~ 55℃ |

| 1.7 |

Mounting: Yoke mounting. |

| 1.8 |

Response time: typically 15 second time constant when exposed to 50%

of LEL |

| 1.9 |

Measuring range: 0 to 100% LEL |

| 1.10 |

Operating humidity range: 10 ~ 95%RH, non-condensing |

| 1.11 |

Input power: DC 12V |

| 1.12 |

Water proof stainless steel water proof housing |

2. Monitors Specification

| 2.1 |

Mounting: flush (rack) panel mounting |

| 2.2 |

Temp. range: -10 ~ 55℃ |

| 2.3 |

Power supply: 110V, 60Hz |

| 2.4 |

Meter span: 0 ~ 100%LEL |

| 2.5 |

Repeatability: ±2% of full scale |

| 2.6 |

Status indicators:

High alarm: flashing LED

Low alarm: flashing LED

Malfunction: flashing LED

Reset button

Press and hold for LED test |

| 2.7 |

% LEL readout: high efficiency digital display calibrated in percent

of lower explosive limit (%LEL) range (0 ~ 100% LEL) |

| 2.8 |

Output:

Continuous adjustable low & high alarm contact and malfunction

relay for external annunciator or shutdown equipment.

Contactor shall be SPDT type, 2A, 120V AC, resistance load |

| 2.9 |

Electrical classification: general purpose for mounting in non-hazardous

area UL certified |

| 2.10 |

Recessed rocker switch

Used for normal operation or calibration. When in CAL mode high

and low alarms are disabled and malfunction-flashing LED |

| 2.11 |

Calibration potentiometer span and zero

Adjustments for each channel accessible through the front panel |

Accept order for other specification or voltage and material.

Galvanized coil tank are available.

STEVE YANG INDUSTRIAL CO., LTD.

TEL: 03-4837888 FAX: 03-4837890

|